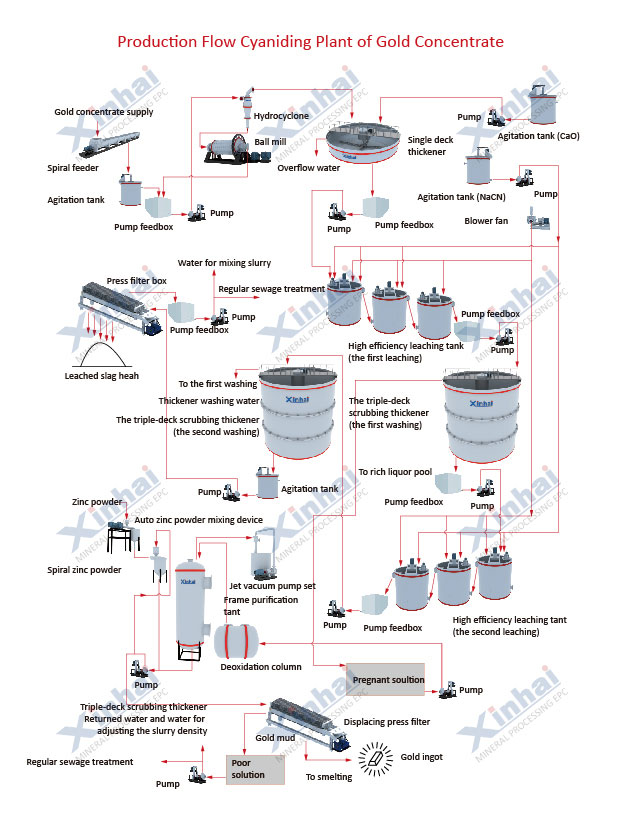

Gold Cyanidation Leaching Process

【Process Introduction】

Gold cyanidation technology is a technology process which put activated carbon into pulp and leaching with absorbing gold at the same time. It includes the stages such as leaching pulp preparation, leaching and adsorbing, gold removal carbon recycling, pulp agitation, and gold loaded carbon desorption.

【Application】

It suits for large gold mines with high grade gold and gold deposits associated with higher concentrations of silver and copper.

[Process Introduction]

1. Leaching pulp preparation

It largely reduces the number of leaching tanks;

It shortens the period of cyanidation and avoids the capital overhang in the gold stranded link. Gold production in a short period and capital returns quickly.

2. Leaching and absorbing

Xinhai special coconut active charcoal has the characteristics including small hole, high activity, wear resistance, and renewable. The absorption rate can increase 30%.

3. Gold removal carbon recycling

It effectively reduce the carbon loss in the continuous pumping and vibrating screening. It reduces the costs and easy to maintain and operate.

4. Pulp agitation

Fast pulp delivery. The pulp circulates slightly;

70% electricity loss is avoided; The solid material homogeneous suspension;

Less loss on active carbon; High gold recovery rate.

5. Gold loaded carbon desorption

99% gold can be desorbed in only 2-6 hours with Xinhai high-temperature high-pressure desorption method(150℃, 0.5Mpa);

The pregnant solution has higher concentrations of gold and silver cyanide complex ions and less impurity ions. Through Xinhai integration high-efficiency and low consumption rapid desoption-electrolysis system, the high purity solid gold can be received safely and economically.

【Project Cases】

In March 2015, Xinhai contracted to build Zimbabwe 700tpd gold processing plant in Africa. The raw ore of this mine is quartzite gold mine, which is most oxidized ore or original minerals with low sulfur content. Therefore the processing technology is combined gravity separation and gold cyanidation carbon-leaching technology, which realizes the high efficiency recovery of gold. The production cost saving is up to 15%. After one year of putting into production, the equipment ran stable, which received the customer satisfaction.

Process Flow>>