gravity-magnetic combined separation

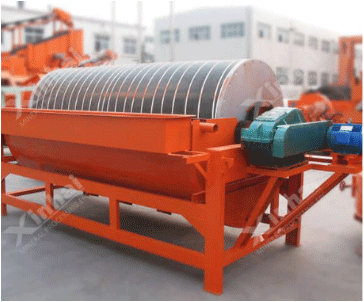

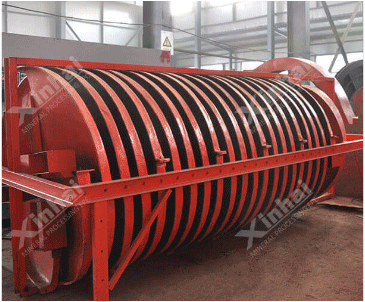

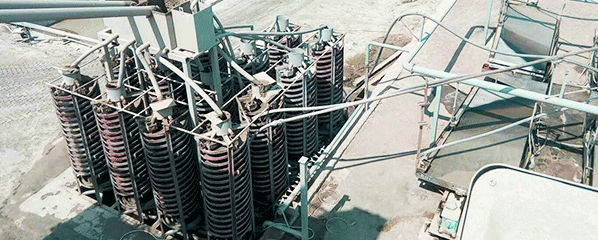

Weak Magnetic – strong magnetic – weak magnetic separation concentrates grinding and shaking table gravity separation – strong magnetic separation concentrates shaking table gravity separation combined technology

Introduction:this technology is magnetic-gravity combined separation technology. Weak magnetic separation can hardly be separated with chrome minerals in coarse grains, which leads an unideal gravity separation index. In order to recover high-grade chrome concentrates, weak magnetic concentrates should be grinded.

Merits and demerits:compared with single shaking table separation, weak magnetic concentrates needs grinded. The equipment investment and production costs are increased, while the grade of chrome concentrates and recovery rate is better.

Whatsapp:+8613641173523

Whatsapp:+8613641173523  xhmineral@ytxinhai.com

xhmineral@ytxinhai.com  Online Inquiry

Online Inquiry