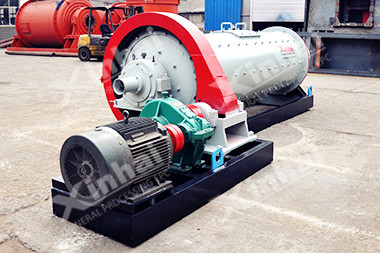

[Introduction]: A high efficiency and energy saving ball mill with rolling bearing

[Capacity]: Up to 160t/h

[Improvement]: Cylindrical energy saving grid ball mill is lined grooved ring plate which increases the contact surface of ball and ore and strengthens the grinding.

The mill with coarse particle product is common used in the first stage grinding

| Model | Cylinder Diameter (mm) |

Cylinder Length (mm) |

Motor Model | Motor Power (kW) |

Length (mm) |

Width (mm) |

Height (mm) |

Capacity (t/h) |

Effective Volume (m3) |

Max. Ball Load (t) | Weight (kg) |

| MQGg 1212 | 1200 | 1200 | Y200L2-6 | 22 | 3512 | 2076 | 1620 | 0.17 ~4.1 | 1.14 | 2.4 | 9610 |

| MQGg 1224 | 1200 | 2400 | Y280M-8 | 45 | 5745 | 2352 | 1778 | 0.26~6.15 | 2.4 | 4.6 | 12692 |

| MQGg 1240 | 1200 | 4000 | JR117-8 | 80 | 7990 | 2210 | 2262 | 0.34~8.3 | 3.8 | 7.8 | 15932 |

| MQGg 1515 | 1500 | 1500 | Y280M-8 | 45 | 5740 | 3075 | 2280 | 1.4 ~4.5 | 2.2 | 5 | 17125 |

| MQGg 1530 | 1500 | 3000 | JR117-8 | 80 | 7253 | 3070 | 2280 | 2.8 ~9 | 5 | 10 | 21425 |

| MQGg 1536 | 1500 | 3600 | JR126-8 | 110 | 8595 | 3185 | 2280 | 3~11 | 5.4 | 11.4 | 24213 |

| MQGg 1545 | 1500 | 4500 | JR127-8 | 130 | 9680 | 3254 | 2370 | 3.5~12.5 | 7 | 12 | 27346 |

| MQGg 1830 | 1800 | 3000 | JR136-8 | 180 | 8250 | 3620 | 2785 | 4.5 ~27 | 6.65 | 14 | 31850 |

| MQGg 1836 | 1800 | 3600 | JR136-8 | 180 | 8866 | 3683 | 2785 | 4.5 ~29 | 8.2 | 13.8 | 35467 |

| MQGg 1845 | 1800 | 4520 | JR137-8 | 210 | 9808 | 3683 | 2785 | 5~35 | 10.2 | 19 | 38909 |

| MQGg 1856 | 1800 | 5620 | JR137-8 | 210 | 10909 | 3683 | 2785 | 6~40 | 12.2 | 22 | 41681 |

| MQGg 1870 | 1800 | 7020 | JR138-8 | 245 | 12404 | 3783 | 2735 | 7~50 | 15 | 31.5 | 45166 |

| MQGg 2122 | 2100 | 2200 | JR128-8 | 155 | 7135 | 4137.7 | 3083 | 5~29 | 6.6 | 20 | 38340 |

| MQGg 2130 | 2100 | 3000 | JR136-8 | 180 | 8220 | 4220 | 3083 | 6.5 ~36 | 9 | 27 | 43100 |

| MQGg 2136 | 2100 | 3600 | JR137-8 | 210 | 9154.5 | 4320 | 3433 | 7.5 ~42 | 10.8 | 23.5 | 45833 |

| MQGg 2140 | 2100 | 4000 | JR137-8 | 210 | 9654 | 4320 | 3083 | 7.5 ~45 | 12.8 | 22.5 | 47262.4 |

| MQGg 2145 | 2100 | 4500 | JR137-6 | 280 | 10350 | 4253 | 3125 | 10 ~50 | 13.5 | 23.6 | 52648 |

| MQGg 2230 | 2200 | 3000 | JR137-8 | 210 | 8220 | 3864 | 3183 | 7.5 ~45 | 9.8 | 20.6 | 44600 |

| MQGg 2430 | 2400 | 3000 | JR138-8 | 280 | 9023.5 | 4836.4 | 3490 | 7.2 ~92 | 11.5 | 22.5 | 59544.5 |

| MQGg 2436 | 2400 | 3600 | JR138-8 | 320 | 9604.5 | 4836.4 | 3490 | 8 ~100 | 13.8 | 25.5 | 63932.5 |

| MQGg 2442 | 2400 | 4200 | JR138-8 | 320 | 10204.5 | 4836.4 | 3490 | 8 ~110 | 16 | 30 | 67370 |

| MQGg 2721 | 2700 | 2100 | JR138-8 | 245 | 8300 | 4786.4 | 3495 | 7.2 ~84 | 10.7 | 23 | 66743 |

| MQGg 2727 | 2700 | 2700 | JR137-6 | 280 | 8901 | 4786.4 | 3490 | 7 ~110 | 13.8 | 29 | 71030 |

| MQGg 2730 | 2700 | 3000 | JR1410-8 | 320 | 9610 | 5000 | 3495 | 8 ~115 | 15.3 | 32 | 83909.2 |

| MQGg 2732 | 2700 | 3200 | JR1410-8 | 320 | 10724 | 5000 | 3620 | 8 ~120 | 15.7 | 32 | 88073 |

| MQGg 2736 | 2700 | 3600 | JR158-8 | 380 | 10409 | 5150 | 3620 | 12~145 | 17.7 | 37 | 95300 |

| MQGg 2740 | 2700 | 4000 | JR158-8 | 380 | 10609 | 5150 | 3620 | 12.5 ~152 | 19 | 42 | 98454 |

| MQGg 2745 | 2700 | 4500 | JR1510-8 | 450 | 11534 | 5200 | 3670 | 13~160 | 22 | 40 | 100016 |

| MQGg 2747 | 2700 | 4700 | JR1510-8 | 475 | 11779 | 5571 | 4175 | 13~170 | 23 | 45 | 101645 |

| MQGg 2760 | 2700 | 6000 | JR1512-8 | 630 | 13299 | 5540.6 | 5140 | 15~200 | 30 | 60 | 119546 |

| MQGg 2836 | 2800 | 3600 | JR1510-8 | 400 | 10964 | 5350 | 3670 | 13~160 | 19.7 | 41 | 106350 |

| MQGg 3231 | 3200 | 3100 | TDMK630-36 | 630 | 12750 | 6750 | 5150 | 14~180 | 22.5 | 45 | 115430 |

| MQGg 3245 | 3200 | 4500 | TDMK800-36 | 800 | 13896 | 7200 | 5152.5 | 95~110 | 32.8 | 65 | 147588 |

| MQGg 3645 | 3600 | 4500 | TDMK1250-40 | 1250 | 18280 | 7700 | 5496 | 115~170 | 41.5 | 76 | 195727 |