【Xinhai Case】Indonesia 700TPD Gold Pool Leaching Project

Indonesia consists of 17508 large and small islands between the Pacific Ocean and the Indian Ocean. As one of the countries along the Belt and Road, Indonesia and China has a large cooperation area in infrastructure, and also becoming new partners in the mine industry.

At present, in Indonesia, there are more and more Chinese enterprises. Xinhai Mining is also one of them. In 2015, Xinhai Mining already entered the Indonesia market, and successively undertaking Indonesia 100tpd gold project and Indonesia 300tpd gold CIL project, which led Xinhai Mining entered Indonesia and Southeast Asia market.

Project Background

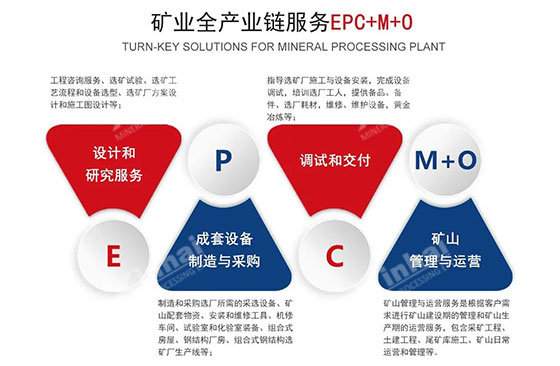

At the beginning, the client contacted Xinhai Mining, and learned about Xinhai Mineral Processing EPC+M+O service, including design and research, complete equipment manufacturing and purchasing, commission and delivery, mine operation and management. The client was very interested in this unique service model.

Xinhai technical staff introduced them mineral processing EPC+M+O service in detail, and provided a proper solution in time according to the past project experience in Indonesia. The client said that the professional strength of Xinhai Mining left a deep impression on them.

Later, the client visited Xinhai Mining to know more about the mineral processing technology strength, which affirmed the determination of choosing Xinhai. After comparison and considerations, both sides successfully reached cooperation. Xinhai provided the mineral processing EPC+M+O service for the client.

Project Overview

Ore characteristics: Gold is the only recoverable element, and the grade is 2.6g/t.

Capacity: 700tpd.

Xinhai solution: Crushing and washing – pool leaching and absorption – desorption electrolysis – activated carbon acid-washing and regeneration – smelting.

Main equipment: Hammer crusher, cylindrical screen, agent agitation tank, carbon absorption column, acid-washing tank, cone agitation tank, high-frequency gold smelting furnace.

Xinhai solution

According to the result of mineral processing experiment, and combined with the consideration of investment cost and profit, Xinhai designed the processing flow of crushing and screening – pool leaching – absorption – desorption electrolysis – activated carbon acid-washing and regeneration – smelting.

1.Crushing and washing

Cylindrical screen is used as washing equipment. The large particles are crushed by hammer crusher. Raw ores smaller than 150mm are crushed into mineral particles smaller than 5mm. The concentration is 35%. The regular pulp is sent to the leaching pool by alloy pump.

2.Pool leaching – absorption

The pregnant solution amount is 40m³/h, and sent three absorption column by chemical pump.

3.Middling and barren solution absorption

After absorption, the middling solution is sent to the middling pool. Through the circulation of the chemical pump, the barren solution enters the barren solution pool regularly, and discharges after removing CN-.

4.Desorption electrolysis

The gold-bearing carbon is handled by desorption electrolysis system.

5.Activated carbon acid-leaching and regeneration

The activated carbon acid-leaching and regeneration has the same capacity with the desorption electrolysis system.

6.Smelting

After smelting, the gold ingot purity is over 80%.

Project Characteristic

1.The designed solution is customized and reasonable

Combined with the relative law and regulations and the development, the mineral processing EPC+M+O service from Xinhai Mining was corresponded to the local mining development condition. It considered the actual situation of the client and designed reasonably. The designed solution was optimized and saving equipment, which largely reduced the operation costs.

2.Customized technology, reasonable equipment and saving investment

Xinhai Mining keeps the principle to reduce investment cost as possible, designed gold pool leaching technology for this processing plant. This technology is simpler than CIP technology and reducing investment costs. It can reach the requirement of processing plant. Xinhai Mechanical Design Institute also improved the equipment according to the actual production relatively, satisfying the technological conditions, and keeping the stable and high-efficiency operation of the whole project.

3.Overcoming the difficulties and successfully output of gold during the outbreak

During the outbreak, the installation and debugging team of Xinhai Mining overcame the difficulties to make sure the schedule of installation and debugging, and had gold output. The installation and debugging plan was successfully finished.

Result

At present, the Indonesia 700tpd gold project successfully puts into production and operation. The processing plant operates stable, and the equipment quality is stable. The processing index and efficiency benefit is up to the anticipation. The actual recovery rate is 85%. The professional mineral processing service strength of Xinhai received great credit. At the same time, Xinhai keeps a high level and high quality professional manner in the special period, which deeply impresses the client.

Till now, Xinhai Mining has served over 2000 mines, over 500 mineral processing EPC+M+O projects in over 90 countries all over the world, involving over 70 kinds of ores. This cooperation with the Indonesia project, Xinhai Mining firms the development in Indonesia. Xinhai mineral processing EPC+M+O service is also highly focused by the Indonesia mining market. In the future, Xinhai Mining will root in the countries of Southeast Asia, taking it as our duty to spread correct mine construction ideas and methods, pushing the practice of Xinhai solution, providing more complete and professional mineral processing EPC+M+O service for global clients and contributing to construct the community of global mining industry development destiny.