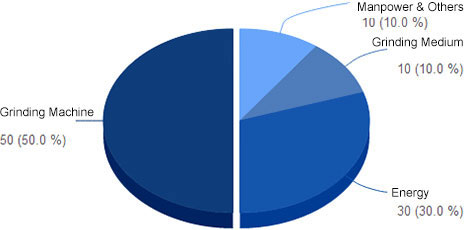

According to the relevant data analysis, grinding mill has an impact on grinding cost and performance, accounted for 30% in overall mineral operating costs, accounted for 50% in whole grinding cost, so the grinding mill has a great influence on manufacturing operating rates, total grinding efficiency and total operation cost. Making a reasonable choice of grinding mill, reducing the grinding cost are an important way to improve your mineral processing efficiency.

After 20 years of hard work, Xinhai Mining has researched and developed all kinds of new energy-saving grinding mill according to the characteristics of the ore materials. Four series of grinding mill are now available:

The new type grinding mill researched by Xinhai fully meet all grinding requirements in mineral processing plant with energy-efficient feature and favorable prices.

big ball mill outler with large production capacity, up to 160t/h

Adopts high strength steel plate with good plasticity and strong impact resistance

Adopts high strength forging steel ball, long lifetime

The small ball mill, whose diameter is less than 2.1 meters (excluding 2.1 meters), adopts the overall frame, easy for civil construction and equipment installation;

High strength, strong wear resistance and good processability

groove-type circular lining plate enhances grinding action and ore lifting capacity and decreases energy consumption.

Xinhai energy-saving ball mill machine is divided into energy-saving grid type ball mill and energy-saving overflow ball mill.

You can refer the following characteristics of the each ball mill machine to select the most suitable one.

Discharge grid, less grinding, preventing the ball from discharging; High efficiency and energy saving, forced discharged, coarse grinding size, and great production capacity

Reverse spiral impeller, returns the steel ball and coarse ore to ball mill; High efficiency and energy saving, self discharging, fine grinding size, smaller production capacity

【Application range】Rod mill is used in the first section grinding of two stage (or three stage), especially suitable for processing brittleness ore materials.

【Application range】Fit to the coarse crushing after coarse grinding, capable of processing most of metal ore, especially iron ore with larger density, suitable for larger mineral processing plant

【Application range】Mainly used for powder processing of materials in such industries as construction, chemical, metallurgy, mine, and thermal power.

Xinhai Mining has got ISO9001:2015 quality management system certification with high quality products, and be classified as advanced products, standard quality and assured brand!

"Create international brand, based on global market" has been one of the strategic thinking of Xinhai. Xinhai has exported beneficiation equipment to Russia, Mongolia, Kazakhstan, Chile, Brazil, Vietnam, Iran and more than 90 countries.

√ Security always is a standard Xinhai advocated and adhered

√ Reduce the risk of engineering safety and equipment

√ Prolong equipment life, shorten replacement cycle

√ Choose the ball mill type according to beneficiation demands

√ Equipment installation, system monitoring

√ Design optimization

√ Assist to choose the best grinding medium based on the characteristics of ore and mill

√ High technicians ensure reliable installation, commissioning and trial operation

√ Reduce maintenance time, improve the production

Please leave your message here! We will send detail technical info and quotation to you!