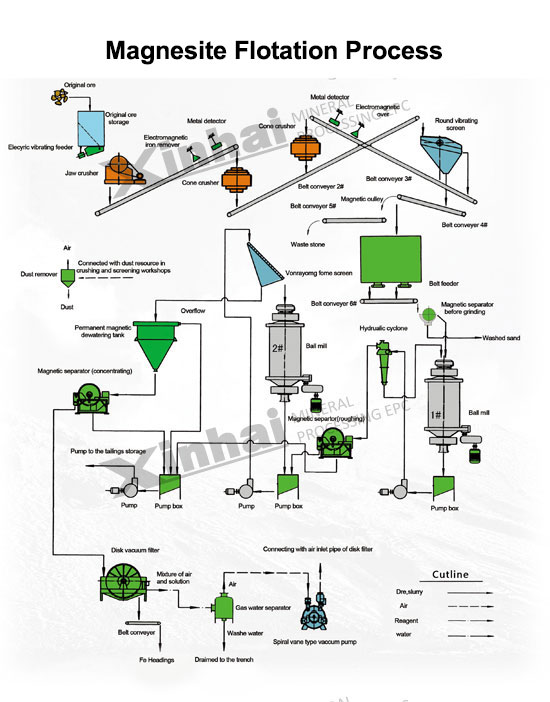

Magnesite Flotation Process

【Process Introduction】

Magnesite is a carbonate mineral. Xinhai mainly applied direct flotation process and Reverse Flotation Process for beneficiation of magnesite.

【Application】

Reverse flotation process is applied for high grade ore with less calcium & iron (Fe). As for low grade ore, Xinhai combines the two methods. Reverse flotation process removes material containing silicon while direct flotation process remove material containing calcium and iron (Fe).

[Process Introduction]

Magnesite Flotation Process- Crushing and Grinding Process

Crushing: raw ore (less than 200mm) go through the two stages one close circuit process, which include jaw crusher and vibrating screen. And then broken to 10~0mm.

Grinding: the crushed ore will closed-circuit grinding, in which ore will be ground to -200mm 70%, then into flotation process;

Magnesite Flotation Process- Separation Stage

In this stage, the main equipment is floatation, agitation tank, thickener. The following two methods is the designed magnesite flotation process by Xinhai.

High grade magnesite ore flotation process: the grinding fine ore will feed into agitation tank, and meshed with flotation reagent. Reverse flotation will get the concentrate ore pulp. Then pulp will transport into thickener and reduce the water.

Low grade magnesite ore flotation process: the impurity in raw ore cannot be removed if only apply the methods of reverse flotation process. So for the low grade magnetsite, Xinhai usually combine the two methods, reverse flotation process (one roughing – one cleaning) & direct flotation process (one roughing - one scavenging). In the process of reverse flotation separate part of tailings, while direct flotation gain concentrate magnesute and middling.

Process Flow>>